by Kip Hanson >> Photos Siemens

Is AR/VR about to transform manufacturing? It depends on whom you ask.

Making the AR/VR case

Perhaps the best way to answer at least some of these questions is to don an Oculus Quest 2 headset or equivalent, download a copy of Vader Immortal or The Climb, and start exploring. It’s there that you’ll see an array of virtual worlds ranging from the photo-realistic to the cartoon-like, all of which are immersive and, as Forbes magazine puts it, transportative.

Doing so might turn you into a gaming fan, but it’s just as likely you’ll find yourself searching for the virtual machine shops and sheet metal houses in these digital spaces. For these, you’ll need to contact technology firms such as Sixense, VRSim, Sightcall, and Librestream, all of which specialize in AR/VR for industrial applications.

These companies offer a broad set of use cases, among them remote assistance with commercial vehicle and equipment repair, welding and spray paint training, remote auditing and inspection, design collaboration, assembly instruction, and many others. All serve to reduce training costs, increase efficiency, and in several notable examples, have even helped companies deal with pandemic-related travel restrictions.

These companies offer a broad set of use cases, among them remote assistance with commercial vehicle and equipment repair, welding and spray paint training, remote auditing and inspection, design collaboration, assembly instruction, and many others. All serve to reduce training costs, increase efficiency, and in several notable examples, have even helped companies deal with pandemic-related travel restrictions.

The hard digital truth

Despite these successes, Eran Nadel, director of Innovation Projects and Rapid Development manager at Siemens Digital Industries Software, notes that VR does a great job for virtual work instructions, training, and the like, but it’s AR technology that still has a ways to go. That’s because AR, which overlays digital representations atop objects in the physical world—thus “augmenting” reality—must overcome a range of technical challenges if it is to achieve widespread industry adoption.

“Many people are looking at AR because they heard about it in a magazine, or maybe they saw a marketing movie in which a worker is wearing an AR/VR headset that displays all these beautiful digital images,” Nadel says. “The fact is, life on the factory floor is much more complicated than that, and there’s a significant gap between the industry’s expectations and what the technology can currently provide.”

Some of this gap is due to a shortage of the highly accurate 3D models needed for AR. Similarly, locational information of physical objects might be missing or wrong, making it impossible for the virtual architect to construct a true representation of the environment. And despite ongoing hardware advancements, the AR/VR headsets themselves create constraints with accurate rendering and tracking.

“In the gaming world, you don’t especially care if the Pokémon is ten centimeters too far to the left or right,” says Nadel. “Not so in manufacturing. Here, customers often require precision to a fraction of that amount. They also need to deal with a constantly changing environment, with real-time information updates. Developing an accurate AR model is a little like building a house where other people are constantly changing the design. It’s quite demanding.”

![]() Conquering the challenges

Conquering the challenges

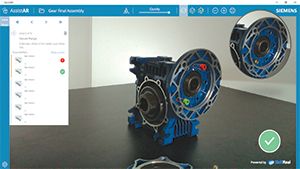

Still, Siemens is one of many companies that is “all in” on AR/VR. For example, it has partnered with Cortona3D, a developer of authoring and publishing solutions for manufacturers wishing to develop AR-enabled content. There’s the German firm REFLEKT, which creates visual guidance tools for frontline workers. And Israel-based SkillReal worked with Siemens to develop AssistAR, an assembly line solution designed to “easily deliver live assembly, inspection and maintenance procedures using highly accurate augmented reality work instructions,” as well as a “Digital Alignment” tool for faster commissioning of production lines.

Some of these have bypassed the traditional AR/VR headset approach in favour of tablet PCs and other mobile devices. According to Nadel, these provide longer battery life and greater accuracy, and can more easily be equipped with advanced features such as cameras and lidar. This makes them more suitable for many of the AR applications just mentioned, although headsets remain a valuable technology for training and work instructions.

Keep ‘em separated

Keep ‘em separated

Tali Segall, vice president of Innovation at Siemens Digital Industries Software, emphasizes the importance of separating AR from VR. For instance, the latter is an excellent tool for teams collaborating on a project. And as we’ve seen, it’s increasingly common for operator training, for deploying work instructions, and for creating digital twins of parts and assemblies, production floors, machine tools and equipment, and various manufacturing processes, all of which serves to increase visibility, avoid mistakes, and decrease costs.

“In each of these scenarios, the person must be in a secure area where they can be immersed in a virtual environment,” she says. “And that’s the beauty of VR—the immersion and the chance to collaborate. If you want to show a customer what your future factory will look like or they want to work with you on a product design, VR is a perfect tool for that. But once you’re actually on the shop floor, whether it’s to inspect a part or show someone how to assemble or repair a product, then AR is your only option.”

Nadel agrees. “There have been some great success stories with each of these technologies, and there will be many more to come. We’re really just scratching the surface of all that’s possible. It’s just a guess, but from what I’m seeing now, I would say that AR and VR alike will be commonly used on the factory floor—and beyond—in as little as five years. I truly believe it’s the future for a wide range of industrial, medical, and even commercial applications.” SMT