Helix Labs Inc. of Toronto, maker of what it says is the most compact, lightest and safest folding bike available, recently decided to automate its manufacturing facilities to meet demand for cost savings, quality and consistency.

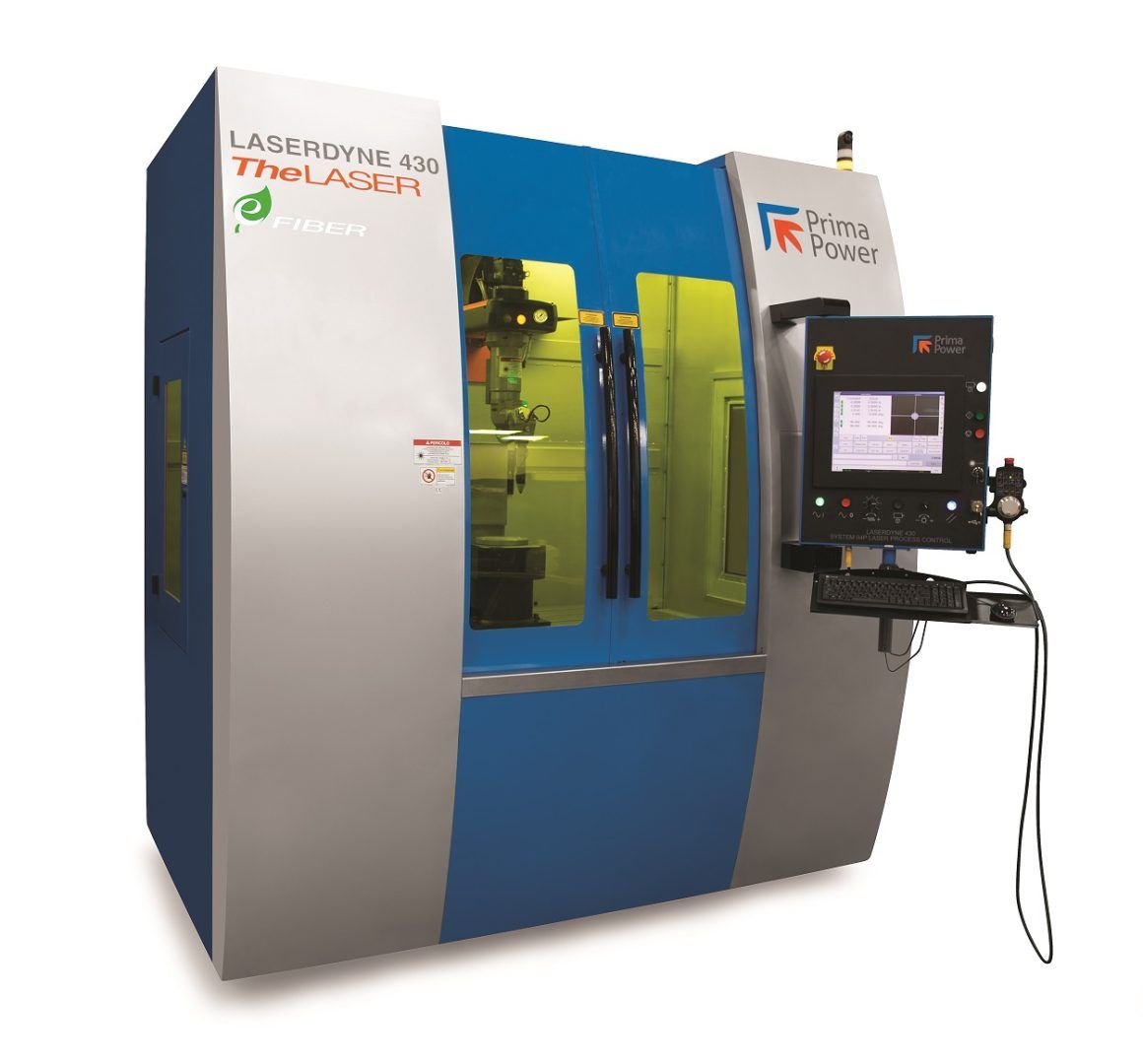

A Laserdyne 430 BeamDirector fiber laser machining system from Prima Power was a key part of the new process in order to precisely bevel cut the titanium tubing used throughout the bicycle.

Working closely with Prima Power Laserdyne applications engineers, Helix created a robust, consistently high quality bevel cutting capability based on the 430BDY system. For Helix, the steeply beveled edges of the titanium tubing required precise and clean cuts to accomplish perfect fit-up of the tubing for accurate robotic welding. Additionally, the 430BD fiber cutting system produces holes and slots in the tubular parts.

But the key is the steep angle bevel cutting of the titanium tubes. This 430BDY capability allowed Helix engineers the flexibility to design the bike assembly for maximum rigidity and strength with the least weight where other tube cutting systems had limited or no titanium angle cutting capabilities. Prima Power says that competing system suppliers failed to develop the required robust titanium cutting process.

“To meet these challenging and different beveled angles, there are unique capabilities within the Laserdyne 430BDY system,” says Corey Hansen, regional sales manager for Prima Power Laserdyne, who helped develop the process.

“A key system feature utilizes a horizontally mounted rotary table with a through bore chuck to accurately locate and hold the titanium tubes for cutting to shape. Titanium is the ideal material for the Helix Bike design because of its high strength, lightweight, remarkable corrosion resistance and unparalleled durability,” Hansen says. “But it can be challenging to process. The 430BD produces the beveled cuts up to 45° from the surface without dross or spatter residue so tubes mated perfectly ready for the automated welding operations. No secondary deburring or tube cleanup was needed prior to welding.”

Another 430BDY feature that came into play is its integrated control of six axis laser motion, allowing Laserdyne’s application engineers to develop the robust and repeatable process for angle-cutting the titanium tubular components. The 430 BeamDirector system incorporates Laserdyne’s BeamDirector, which gives users like Helix the ability not only to bevel cut but also to drill cylindrical and shaped holes and weld a wide range of materials in addition to titanium, all with the same system.

“The 430 BeamDirector is fast, flexible and provides the high quality processing that we needed to produce an industry leading bicycle for our customers,” says Helix CEO Peter Boutakis. “The addition of the 430BD was a critical aspect of our manufacturing and the Laserdyne team showed a strong willingness to partner towards the goal of producing a high quality laser cut. This helped make possible our drive towards a smaller, lighter, safer and easier to use foldable bike.”

Boutakis says Helix has a backlog of over 1700 bike orders. Full production has begun and the company expects to make its first shipments in September.