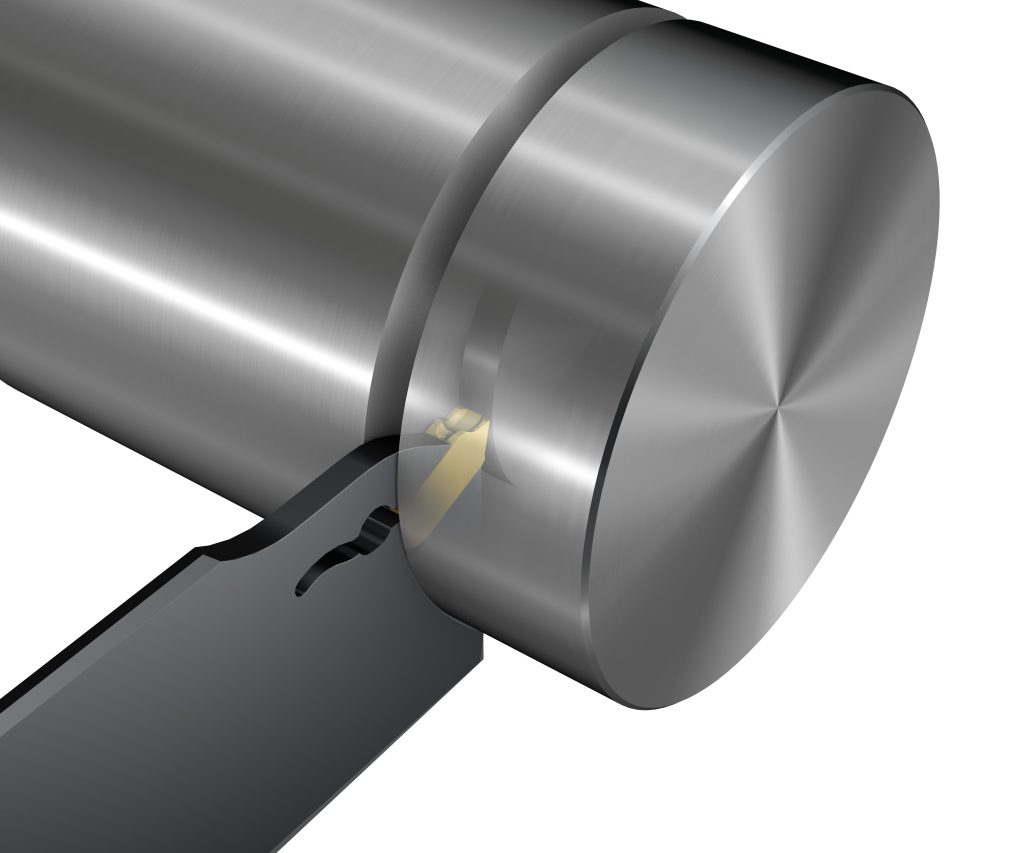

As process security is of high importance, it is preferable to choose a tool with precision coolant. Shown here a CoroCut QD y axis parting with coolant action courtesy of Sandvik Coromant.

This TECH TIPS is provided by the experts at Sandvik Coromant

Parting off is mainly performed in bar feed machines, often used in mass production. The parting off operation is usually only a small part of the component’s total machining time and therefore not usually seen as a target area for time savings. However, after the parting sequence, some components still have additional features to be machined while in the sub spindle.

If chips wrap around the component, they can prevent the clamping of the next component in the sub spindle. If this occurs, the machine will either produce scrap or stop. Chips wrapping around the finished component can cause problems in consecutive operations (heat treatments, deburring, assembly, etc.) and destroy the surface finish.

Since parting off is usually one of the last operations to perform on the component, security is of great importance. If the tool breaks during parting, the component is usually scrapped. This may lead to long machine stoppages.

CoroCut QD - exploded view

How to choose parting tools

As process security is of high importance, it is preferable to choose a tool with precision coolant. This will evacuate chips, reduce temperature and insert wear, and improve surface finish. Use a tool with the shortest possible overhang and a secure insert clamping for best stability.

When parting off a component, bar or tube, it is important to save material and minimize cutting force. A narrow insert creates lower cutting forces and saves material. Choose an insert geometry designed for parting off. These specialized inserts produce chips that are narrower than the groove. This results in a parting off operation with good chip control and surface finish.

First choice for parting off: One- and two-edge solutions should be considered as the first choice for different parting off operations. Use inserts that are designed to produce chips narrower than the groove.

Shallow parting: For shallow parting (diameters ≤ 12 mm, 0.47 inches), use 3-edge inserts for economic parting in mass production.

Medium parting: For medium parting (diameters ≤ 40 mm, 1.57 inches), use screw-clamp and spring-lock holders with 2-edge inserts.

Deep parting: For deep parting (diameters ≤ 112 mm, 4.41 inches), insert stability is crucial as this type of cut places high forces on the insert. Hence, a blade with a stable spring clamp and a single-edge insert is the best choice.

Pip- and burr-free parting: For pip- and burr-free parting, use a sharp geometry with small corner radii. A front-angled insert will also reduce pip and burr. Front-angled inserts will create side forces and are recommended only for short overhangs (< 13 mm, 0.51 inch).

Small part machining: For small part machining, use an insert with the smallest width and sharpest cutting edges. For best process security, use a tool with precision coolant. If superior tool edge sharpness is not necessary, choose a 3-edge or 2-edge insert for a more economical solution, or for larger diameters.